Lets review a few challenges most printers encounter on a regular basis and then explain the advantages the Bison Platen System brings to the table.

Bracket mounting

- Majority of printers are using the bracket and 4 screws into a fiber board. Your support and foundation rely on the holding power of those 4 screws. If you over tighten, you run the risk of compromising that bond.

- On a manual press, you are physically rotating and stopping, putting pressure and stress on that connection

- Some printers have moved to double stick tape setups. When tape gets hot, it gets flexible and reduces the stability of your foundation. Limited options to adjust how level they set as well as locks you in a specific platen size for that setup.

- Tapped threaded aluminum is one of the better options, but has similar issues to the screw situation. Aluminum is a soft metal and if you over tighten you compromise that support. Also being aluminum, you are set to specific platen size

#screenprinting #platen #bracket #brackets #actionengineering #hopkins #rileyhopkins #hivemedia #manualprinting #silkscreen #plastisol #bisonplaten

Boards

- Most presses come with the basic MDF Veneer top boards. These are a nice looking low cost solution to provide a starting foundation for printing.

- Environmental factors impact the integrity of these boards over time. With repeated exposure to heat, cold, humidity and usage the boards tend to warp or disform, creating registration issues and print inconsistencies.

- Aluminum replacements have become the standard upgrade to reduce warping. Aluminum helps to distribute the heat more evenly, reducing hot spots, mainly from brackets. The only down side to switching to this option is the limitation to specific platen size and ability to customize for specific projects / client request and maintenance.

- Rubber top that can blister, deform and time and cost to replace

- Double stick tape gets worn and needs to be replace

- Tap threaded models are limited to torque due to risk of compromising threading

- Then there is the use of ¾ cabinet grade plywood.

- Having multiple bonded layers and a smooth finish top. This gives a locally available and low cost option for a platen. The multiple layers also gives a better grip to support bracket, hot spot impact from bracket is less compared to MDF boards. In time, these boards will also start to warp but not as bad due to the composite of multiple bonded layers.

- Customize size for specific jobs, not eating up profits for expensive limited use boards.

Bison Platen System

Bracket

- screen printing, screen printing platen, screen printing pallet, Hopkins, Hopkins BWM, screen printing bracket, screen printing base, screen printing aluminum platen, printed shirts, t-shirts printing, silk screen shirt printing, manual press, automatic press, Bison Platen, Platen bracket, riley hopkins, hopkins bracket, shirt press bracket, aluminum platen, aluminum shirt board, shirt board, simulated process, plastisol, Graphic Design

- Compact, low profile, normal size knobs and wide footing knob bolt helps with stability when mounted to press arm

- Can be used with the system or standalone. Check out setup video for tips on using as a standalone bracket as there is an additional component to help minimize movement is screw does come loose.

Base Plate

- Bolted to the bracket… yes bolted. Creating a solid foundation.

- Being bolted, the bracket and base plate become one, one solid printing foundation and stability .

- Interior and Perimeter mounting holes to attach you Wood or MDF platen top. These holes are positioned to pull the board flat and keep flat. Mitigating the warping factor.

- The large aluminum base plate help to distribute heat evenly, minimizing hot spots and more uniform flashing, as well as keeping boards heated reducing flash time and increased production speed.

- Not all presses are perfect. At the bolting locations, shims can be added to help level your boards across all arms. See installation video for more details.

- Not set to a specific platen size. Can add or replace as needed based on business needs.

- Base can be used as a Left or Right hand knob side. Base Plate will align center with arm either way.

Youth / Standard / Custom Sets

- Setting up each set to be aligned the same allows for easy change out with no to minimal adjustments. Each base is dedicated to a specific arm.

- Example of printing standard boards for standard shirts, but changing out to a smaller board set to accommodate for fashion of fitted shirts.

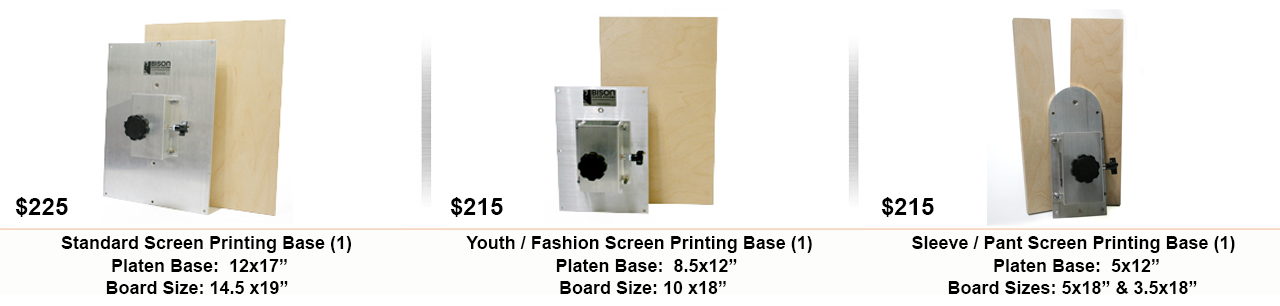

Currently, there are 3 different options. Each option comes with a specific board set.

Check out video on these Platen System sets and watch installation video for more details.